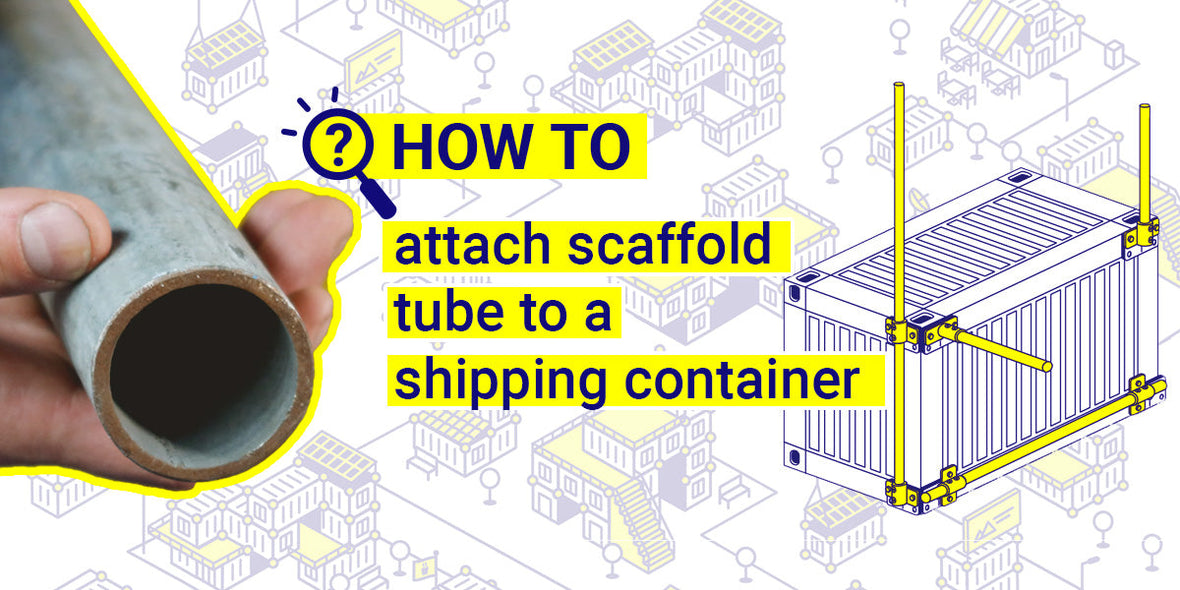

How to attach scaffold tube to a shipping container

Let’s show you how to attach metal scaffolding tube to a Domino Clamp, which is one of the most useful and versatile starting points to help you build further structures, or attach accessories like floodlights, CCTV and signs. It can also be used to tie into an existing scaffolding structure.

What exactly is a scaffold tube?

For those not in a country where ‘tube and fitting’ scaffolding is commonly found, we mean steel tube with a 3.2mm wall and a 48mm (more accurately 48.3mm) outside diameter which, when joined with various types of scaffolding clamps, is used to build scaffolding structures. Identically sized aluminium tube is also quite common and comes with its own set of specialised attachments, this is generally used where keeping weight down is important, such as in the events industry.

Other modular scaffolding systems l (products like ringlock, cuplock and Layher) also use 48mm tube, so there will be some crossover here. Most event rigging companies across the world will be familiar with the aluminium equivalent. There are also modular scaffolding systems using 42mm tube and we have tube clamps available in this size also.

Method 1.1: Using a half swivel coupler with steel tube

One of the easiest ways to fix a scaffold tube to a container is by using a scaffolding half swivel coupler and bolting it to any of the four holes on the Domino Clamp. Half couplers are available in both pressed steel and forged steel variations, both of which will do the job perfectly with steel tubes.

A half swivel coupler - as the name suggests - is just one half of a swivel coupler, used for joining two pieces of scaffold tube at a variable angle , and so they have a hole where the pivoting pin or rivet will usually go to join the two pieces together. Generally, this hole will be about 20mm diameter.

Simply use an M12x16 countersunk screw to go through the hole in the coupler, and tighten it up with an 8mm hex key. Using just one half coupler, there’s not a lot to stop your entire tube from pivoting, so you’ll probably want to be using these couplers in pairs, either vertically or horizontally on the side of the container.

Method 1.2: Using a half swivel coupler with aluminium tube

It's best not to use steel half couplers with aluminium tube; particularly the pressed couplers because they can easily crimp and damage the tube.

Instead, there are loads of aluminium half couplers out there, but we recommend using the Doughty T57000 as it has an M12 hole and a stainless steel bolt, so it is better suited for life outside. That said, Doughty does not recommend it be left outside for long periods of time as it is not designed or rated for long term exposure to the elements, only that it is better suited to this than its clamps with normal non-corrosion resistant bolts.

With these half couplers, use a socket cap screw instead of a countersunk one. For the Doughty T57000 half coupler just mentioned, an M12x35 socket cap screw is what you need.

The half coupler’s bolt will be poking out from the side of the container, so you may want to consider taping this up with some padding if it’s accessible to the public.

Method 2: Using tube clamps

Tube clamps are often called ‘kee clamps’ or ‘Key clamps’ are the most popular way to attach scaffolding tube to a shipping container, and we have a few of these available in our webshop which will easily bolt directly to a Domino Clamp using the set screws we provide with them.

Our full guide showing all our range of tube clamps in different sizes is here in our ‘ultimate guide’ blog, but here we’ll stick to just the one of scaffolding - 48.3mm outside diameter.

Using tube clamps to fix the scaffold tube to a container is neater and more aesthetically pleasing than the half coupler option, as well as removing the small hazard of the half coupler’s bolt thread poking out. In addition to this, this method will also work for aluminium tube, which is why it’s our preferred method.

We offer four main options for attaching scaffolding tube to a container, as illustrated above.

This can be used to attach signs, lighting and CCTV on site, as well as attaching overhead cables so they are up and out of the way of site traffic.

Great for attaching a full length scaffolding tube up the side of a container. This can be used to attach lighting and CCTV on site, as well as attaching overhead cables so they are up and out of the way of site traffic.

This is probably the best option to tie a scaffolding structure to a container. This is extremely strong when using two Domino Clamps. It can also be used to hang decorative banners.

- Instructions

- Ideas for use

- Related products

This option is the least strong of all the options so it is best suited to more lightweight applications such as hanging signage or lighting where it can be seen sticking out from the side of the container, but well above head height.

For further information, including information about what other sized tubes we can help you attach, please next have a look at our Ultimate guide to attaching tube to a shipping container.

For more ingenious container solutions, useful information and offers delivered direct to your inbox, sign up to our information email 📨 or subscribe to our YouTube channel 📺