How can Domino Clamps benefit your shipping container construction project?

1 comment

Developers, architects and engineers have long recognised the benefits of using ISO shipping containers as pre-fabricated building blocks which can be easily manipulated, installed and used for a determined design life and then transported to the next site. The number of construction projects involving standard shipping containers has been rising noticeably over the past 10 years, ranging from bars, hostels, temporary accommodation, site offices and housing developments.

Domino Clamps can be incorporated onto these projects with a range of advantages, from efficiencies to the construction programme to accredited stress tests. Let’s look at a few of these benefits individually:

Off-Site Construction and Efficiencies to the Construction Program

The ISO standards for freight containers standardises the internal and external measurements of all shipping containers. A further ISO standard, ISO1161 harmonises that of the corner castings in all 8 corners of a shipping container. Domino Clamps are designed to fit these corner castings with acceptable tolerances. This allows the consulting designers and engineers to create detailed information packages in BIM or 2D draughting software for any connecting structures.

This way whether you are designing a walkway, canopy or cladding system for your shipping container construction project you will be able to provide the fabricator with a detailed information package early on in the project, allowing them to commence fabrication prior to the units arriving on site, providing a speedy assembly once the construction phase begins.

Factory Load Tested & Guaranteed

The most obvious alternative to using a Domino Clamp to fix something to the steel chassis of a shipping container is a site weld. Apart from the costly sub-contractors required on site which will have to meet all the standards set out in EN 1090 to do the weld initially, once the welding is finished the only way for a client to obtain conformity and quality assurance is to commission a visual examination and non-destructive testing, which normally includes ultrasonic tests which search for surface imperfections, from a 3rd party specialist.

Domino Clamps on the other hand are quick and easy to install and have been strength tested in a UKAS accredited testing house based in the UK, with easy to interpret tech sheets providing the designers and consultants with safe working loads.

Zero Impact to the Structural Integrity of the Shipping Containers

Shipping containers’ primary use is to transport large amounts of goods from Port A to Port B. They get loaded, lifted, stacked, craned, shipped, craned again, lifted and unloaded multiple times during their typical life span. Each element contributes to the integrity of this monocoque structural system, allowing them to endure such a strenuous existence. The cross members spread the floor loads, the rails provide a perimeter sub-frame for the steel panels, the panels act as deep beams and rigid diaphragms and the corner castings and forklift pockets allow for lifting. Any physical modifications made to a shipping container chassis will have an effect on its overall structural performance, whether it be a weld, a drilled hole or a cut out.

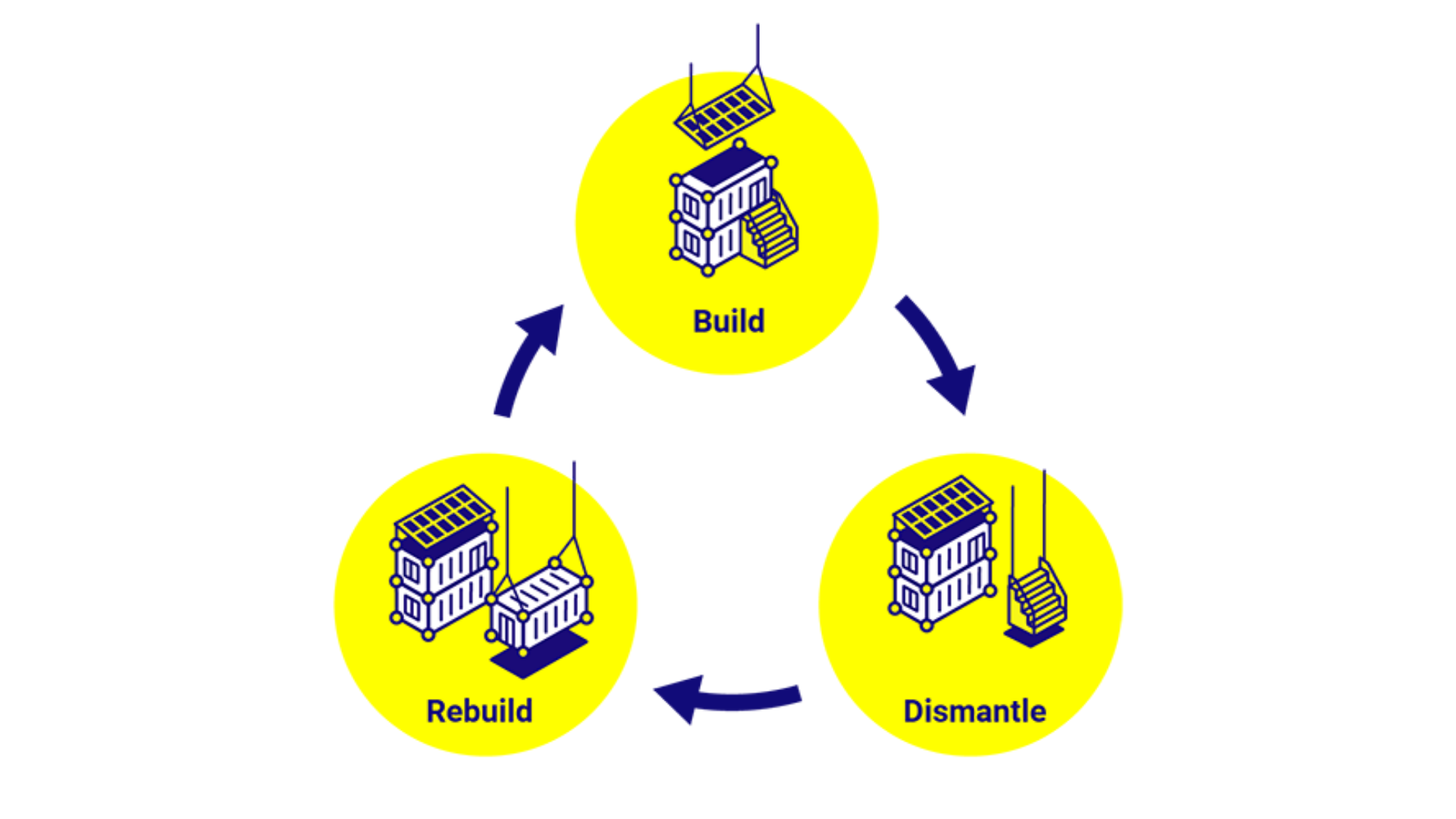

With Domino Clamps' unique fixing method, where an external fixing plate is fitted to the container by clamping into the corner castings, it can be installed and removed again and again with zero impact on the structure of the container. This not only facilitates the transportation of the container between sites, but also allows the designers to be versatile in their solutions between projects to meet demanding clients' fluctuating requirements.

Overall the benefits from using a Domino Clamp fixing in a construction project comprising ISO Containers are overarching to the needs of designer, engineer, fabricator, contractor and client. Their ease of use, quality assurance and long term advantages deliver an ideal product to include at the concept stage of your shipping container project, whatever you want to use your container for.

For more ingenious container solutions, useful information and offers delivered direct to your inbox, sign up to our information email 📨 or subscribe to our YouTube channel 📺

Comments (1)

Hi

Great product. I am looking at attaching a roof to a 20 ft container without welding or drilling into the container. Would the Domino clamp be suitable? If so were would I buy the clamps in Australia?

Cheers Malcolm