An introduction to shipping container corner castings

What is a corner casting?

ISO1161 corner castings are the big three-holed blocks of corten steel which form the corners of all ISO shipping containers. Cast from corten steel, usually in India or China and weighing 2.5 kg (23lb) they are the structural elements that are used to lift shipping containers as well as to connect them to whichever mode of transportation is being used to move the container such as ships, trains or road vehicles. They are also the connection point for shipping containers to be attached to each other, as in the case of stacks of containers aboard a container ship.

Want to attach something to a shipping container?

No welding, no drilling required:

View our new Shipping Container Brackets here

In order that all lifting and container transportation equipment works properly across the world, these corner casting have holes in them which have been standardised to a tolerance of mere millimetres. It is because of this standardisation, that no matter what you need to attach to your container, and no matter where in the world you are, Domino Clamps are guaranteed to be compatible with your ISO shipping container.

Where will I find them?

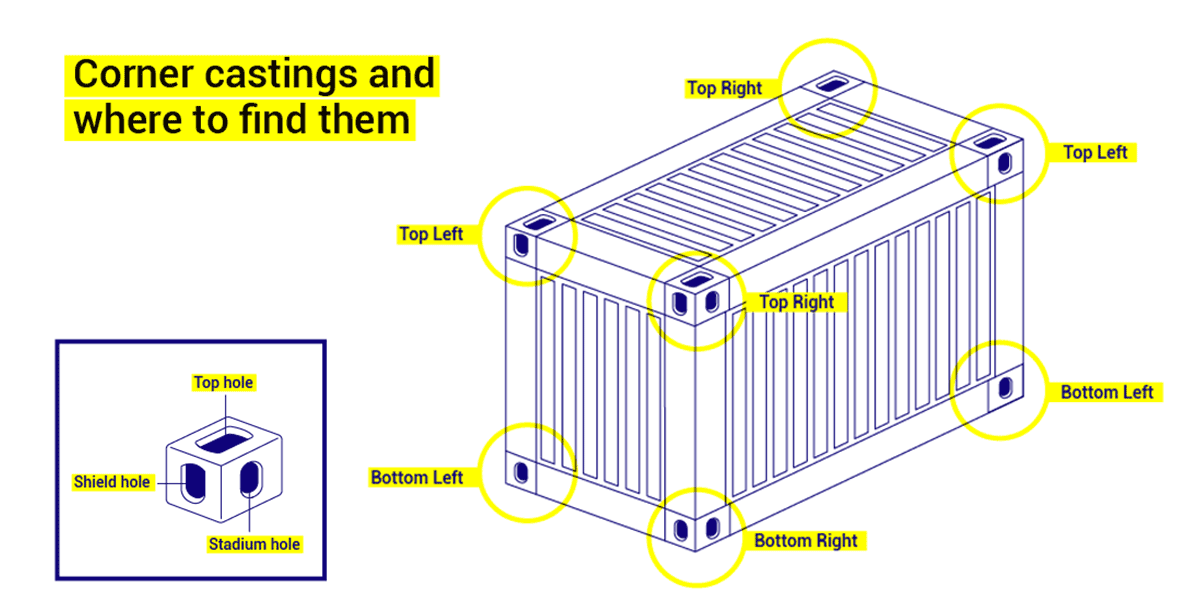

Corner castings are found on all eight corners of an ISO 6346 shipping container. They each have three holes, one in each side of the outward facing surfaces of the casting. Sometimes, non standard containerised units will also have been made using ISO1161 corner castings. Domino Clamps will work in these as well but we advise that you exercise caution and take advice from the container manufacturer that the container itself can sustain the forces you plan to apply to the Domino Clamps, which have been carefully and rigorously tested to ensure that they are more than capable of securing the loads laid out in our technical sheet.

Are all the corner castings the same?

There are eight ISO corner castings in total: top left, top right, bottom right and bottom left. The descriptions relate to the position of the castings as on the end and door faces of the container, as you look at the container from the outside. Each shipping container uses two of each of the four variations.

The most notable difference is between the top and bottom corner castings. While the bottom castings have two stadium shaped holes on two sides (plus a large stacking hole underneath), the top castings have two differently shaped holes on the side, and the stacking hole on top. The top castings have a stadium hole on the long side of the container, and a shield hole on the front or rear end of the container. It is important to note that Domino Clamps fit both the shield AND and stadium holes, but NOT the much larger stacking holes on the top of the top casting and the underside of the bottom castings.

The left and right castings, both top and bottom are just mirror images of each other but are the same in all other respects. If you are unsure which casting you are looking at, it will have been cast with two letters on the inside which will be visible when looking in through the stacking hole; TL for top left; TR for top right; BL for bottom left; and BR for bottom right.

How do I know if my shipping container is ISO standard?

If your shipping container is made to ISO standards it will have a code printed on the top right hand corner of the door as you look at it from the outside, it will also appear on the top right hand corner of the side of the container under the container number. Check our blog about how to identify an ISO shipping container for more information If you are still unsure about this, simply email us with pictures of your container and we will do our best to let you know.

Do Domino Clamps work with other types of corner fitting?

There are various other types of corner fitting often found on containerised units, which to the untrained eye may look the same or similar to an ISO container. Check the thickness of the steel at the stadium hole, if it is thin, anything less than about 18mm, then it is most likely not an ISO corner casting. Again, if you are unsure or have any other questions, please feel free to contact us and ask.

And how do Domino Clamps attach themselves to the corner castings?

The Domino Clamps have a rotating clamping plate which is inserted into the stadium or the end holes of the corner casting and is done up with a hex key to tighten it onto the side of the casting. There’s a simple explainer animation showing how this works or you can watch Chris fully show you round the product in our full instructions on how to use Domino Clamps.

For more ingenious container solutions, useful information and offers delivered direct to your inbox, sign up to our information email 📨 or subscribe to our YouTube channel 📺