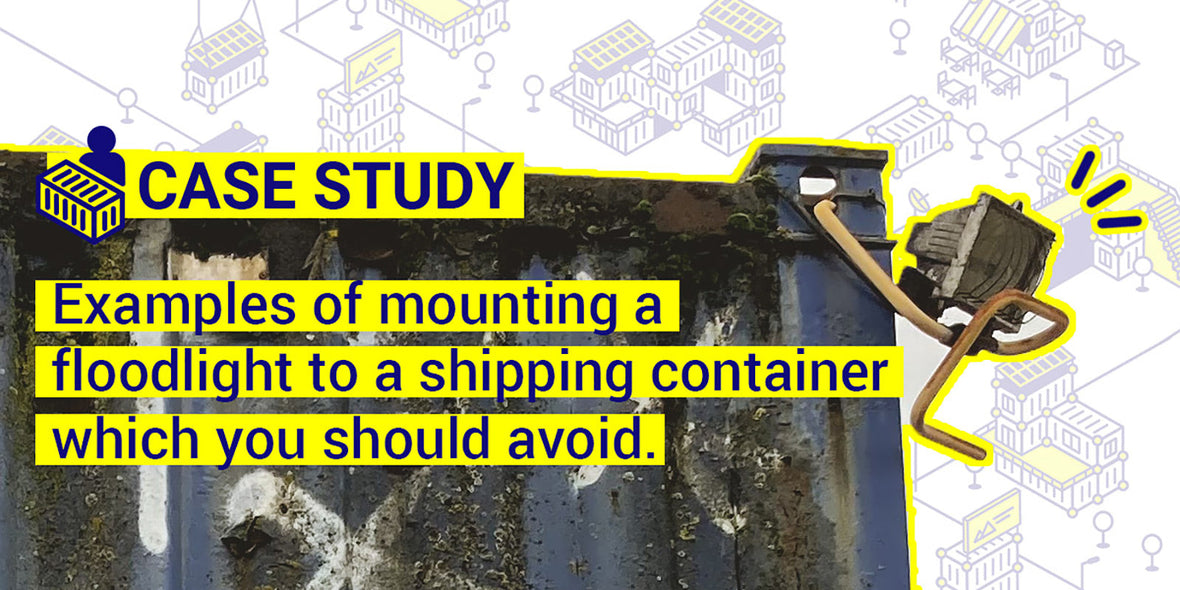

Examples of mounting a floodlight to a shipping container which you should avoid

When we first came up with the idea for Domino Clamps, one of the first things we used them for was to attach large metal halide floodlights to shipping containers at events. Working into the evenings, we needed as much light as possible to work safely, and although we had plenty of lighting, it wasn’t as safe or as efficient as it could be. With the first Domino Clamps prototypes, we could get our floodlighting higher and safer than before.

Here are some examples of poorly erected floodlights we have spotted in the last year, along with an explanation of why these methods are best avoided.

G Clamps

This small flood light had been attached vertically using a G Clamp. This type of lighting bracket is common in the events industry but is designed so that the light hangs from it, not stands on top of it. It is also designed to attach to metal tube; the corner of a shipping container is completely the wrong size and shape for this to safely grip to, especially with the weight of a flood light on top. A tug on the power cable, some wind or a knock to the container itself could mean that the G clamp slips and the flood light falls on someone’s head.

A single Domino Clamp and floodlight bracket would hold this floodlight much more securely and also get it higher so that the light has better coverage.

Zip ties/cable ties

Cable ties are truly wonderful inventions, but they are not the right tool for the job to permanently attach a flood light to a container. This one was barely holding the metal stand in place. The yellow bracket for this floodlight was designed for it to sit on the ground, not to dangle like this 5m in the air.

Attaching a floodlight using Domino clamps and a steel tube using a double tube clamp kit, also means that the cable can be run neatly and safely down the pole, so there is not a power cable permanently dangling loosely out of the fixture.

Also, when using our Domino Clamps and floodlight brackets, it is much easier to point the light wherever it's needed vertically and horizontally, rather than relying on how it happens to hang off the container.

Custom made brackets and bolts

Although this is the best of the ‘bad’ examples of attaching a floodlight to a container that we have seen so far, it's still not ideal. Drilling into a shipping container wall is a surefire way to shorten the lifespan of your container, and will lead to rust and water ingress. Besides, if it's not even your shipping container container then drilling holes into it is definitely best avoided!

Also, this bracket looks homemade; Why not save the hassle and get a kit that was designed for this job and with everything you need directly from us?!

For more ingenious container solutions, useful information and offers delivered direct to your inbox, sign up to our information email 📨 or subscribe to our YouTube channel 📺